How a Grease Trap Works?

What is a Grease Trap?

Grease traps or grease inceptors have been in use since Victorian times.

Grease traps vary in size, with smaller variations designed to connect individual sinks and larger ones installed to service larger facilities.

The definition of a grease trap is "a trap in a drain or waste pipe to prevent grease from passing into a sanitary sewer lines and system."

A grease trap/grease inceptor is in simple terms a plumbing fixture that contains decomposing food waste, bettering the sewer system.

What is The Purpose of a Grease Trap/Grease Inceptor?

The wastes in food solids, even oils and grease, generated by large establishments such as schools, cafeterias, and restaurants is significantly more in both frequency and volume. If left unchecked, the food solids could end up accumulating in sewer pipes and create sewer system problems such as:

-Foul Odors

-Blocked drainpipes and sewers

-Restricted flowing rate of wastewater

To prevent these problems from arising it becomes necessary to get specialized devices installed. The device in question is called a grease interceptor or a grease trap (these terms are used interchangeably).

Health inspectors typically ensure that large establishments have grease traps (or grease inceptors) installed on their premises.

How Does A Grease Trap Work?

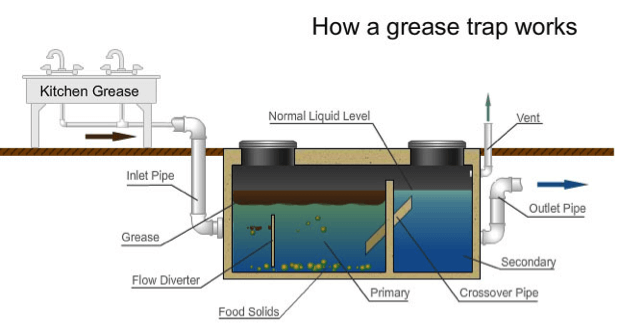

In the most fundamental term, a grease trap or grease inceptor functions by cooling warm or hot greasy water. By allowing the fat, grease and oil (FOG) to cool, a grease trap is able to separate the different layers of wastes with water.

FOG are lighter in density and float at the surface of the tanks, and the cooled water – minus the FOG - continues draining to the sewer system.

FOG float to the top of the water are then trapped by the grease trap. For its use to be effective, the grease trap/grease inceptor should be emptied when the sludge level reaches 25% of the tank level.

The larger “gravity” or “passive” traps rely more on gravity and time to separate FOG. Standpipes, internal baffling, and larger tank sizes allow the magic of gravity to work by increasing the “retention time” on these passive grease traps/grease inceptors. The services of a professional should often be sought at intervals.

For smaller, indoor types a hydro-mechanical grease interceptor should be used instead. The traps used in the interceptor utilize internal baffles that provide more space and time for separation by lengthening the circulation path and maximizing the flowing rate.

In order to maximize separation of FOG from effluents, the wastewater making its way inside the grease trap should be regulated by control devices that at this stage also allow mixing of air.