Novel microbial carrier - “the most efficient for degradation of waste water base value”

MBC microbial carrier produced by German company is the microbial carrier with the highest effective surface area (> 5,500 ²/m³) on the market at present, and has the degradation efficiency of ultra-high pollution value.

v Very large effective surface area

v Ultra-high microbial treatment efficiency

v The quantity required for a smaller volume

v Save civil construction costs

v Special shape design

v Optimum transfer thickness

Product introduction

v Very large effective surface area

Each cubic meter of MBC microbial carrier has an effective surface area of > 5,500 m2/m3 (the area of fine pores on the surface, the habitat space of microbial film), with a total number of about 1,000,000 pieces and a weight of about 170kg.

v Ultra-high microbial treatment efficiency

The basic value degradation efficiency of wastewater is the highest, and the super-large COD volume load (COD removal and degradation efficiency) is 20-200kg /m3 per day. Ammonia nitrogen (NH4-N) volume load (ammonia nitrogen removal and degradation efficiency), up to 4-5 kg/m3 per day, than any other brand carrier is more than five to ten times larger, as the biggest feature of this MBC microbial carrier.

v The quantity required for a smaller volume

Compared with traditional microbial carrier, MBC microbial carrier only needs 1/5-1/10 of the amount of traditional microbial carrier to achieve the same capacity.

v Save civil construction costs

The need for tank volume is minimal, which saves land and construction costs. Or the existing activated sludge aeration tank only needs to add this carrier, and no additional expansion is required, which immediately improves the capacity and efficiency of the existing tank.

v Special shape design

Round and flat parabolic shape, with the specific gravity of the carrier close to 1, the best drift in water, by aeration or agitation in the tank, can drift in all directions in the tank, similar to Pu Gongying drifting in the wind.

v Optimum transfer thickness

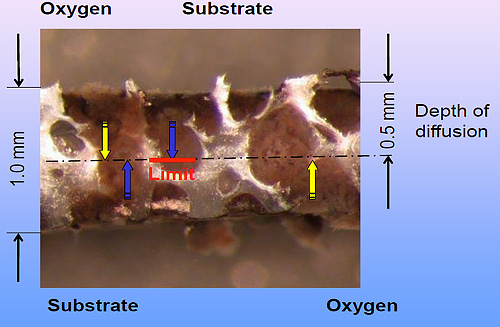

The transfer distance between oxygen and substrate (contamination value) is only 0.5mm (the optimal thickness of microbial film attached to the carrier surface), the optimal thickness of microbial film = the best water treatment effect (as shown in the figure below)

The application of microbial vectors in the reaction tank

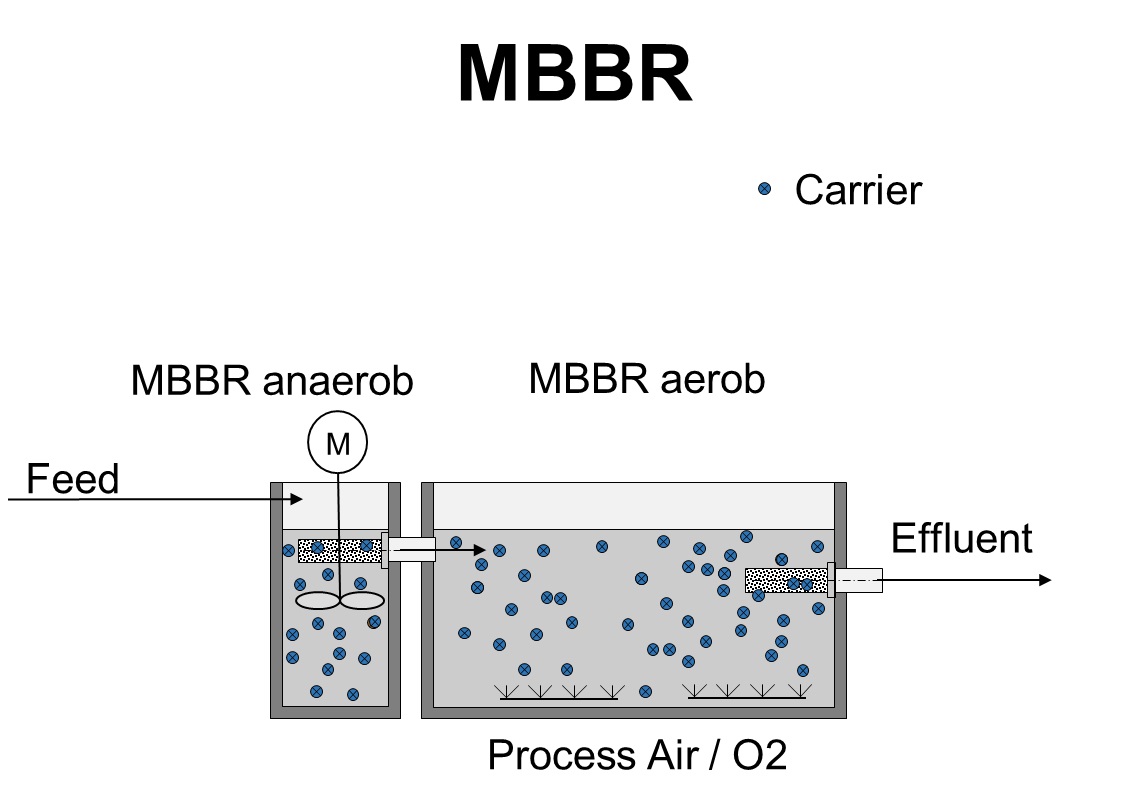

Moving Bed Bio Reactor (MBBR) Moving Bed Bio Reactor (MBBR)

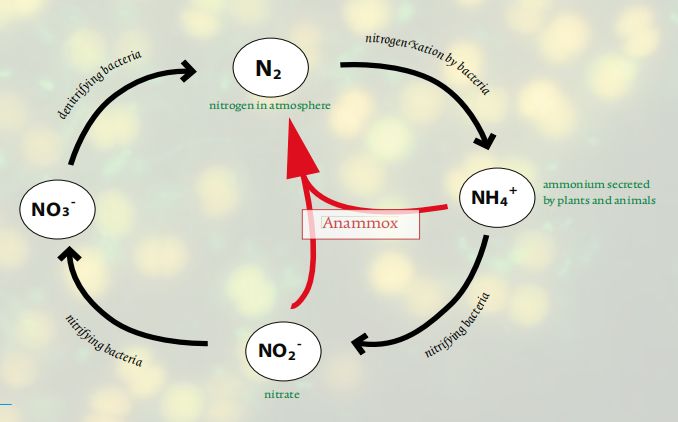

Anaerobic Ammonium Oxidation tank (Anaerobic Ammonium Oxidation, Anammox)

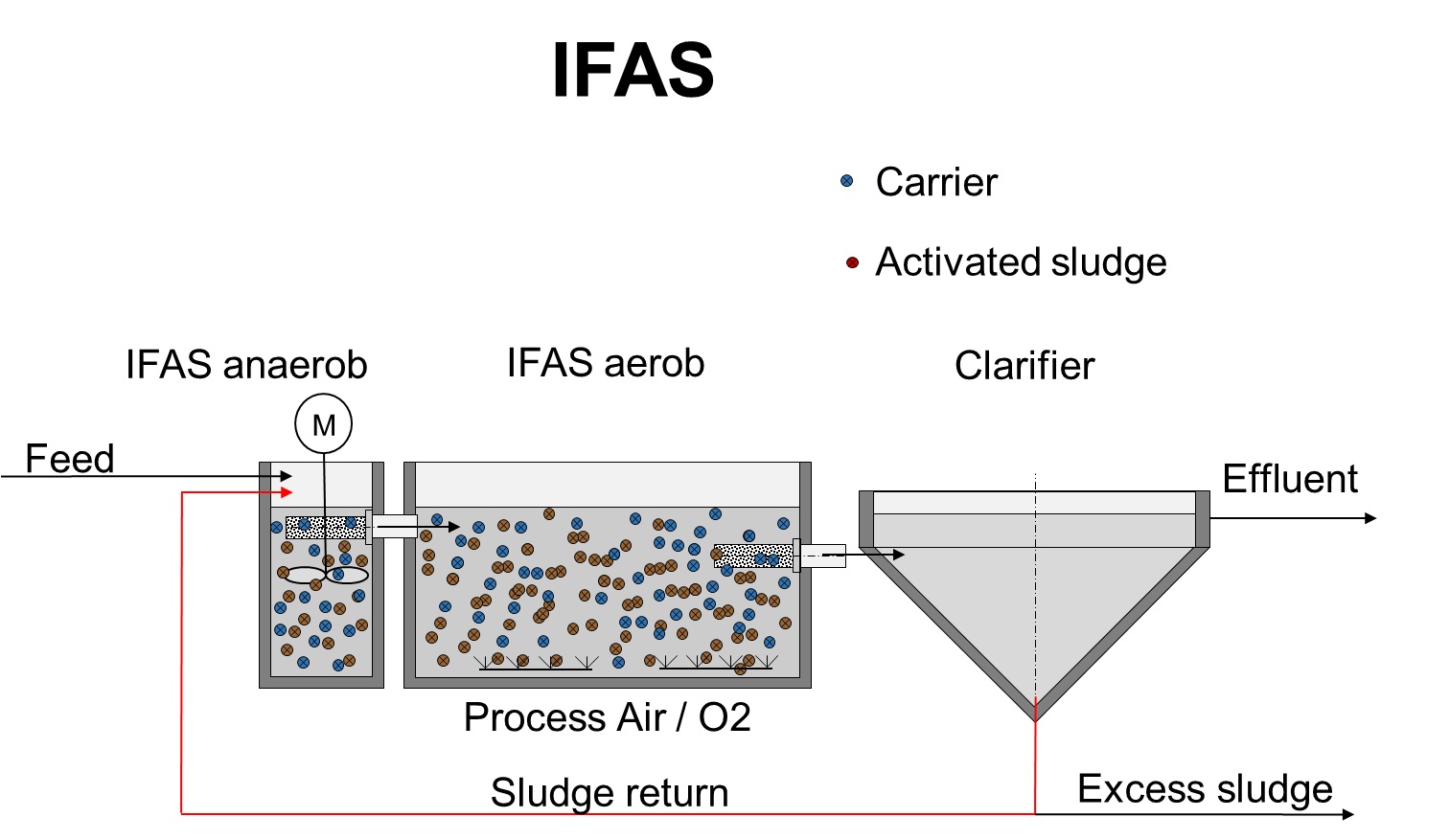

Integrated Fixed Film Activated Sludge System (IFAS)

Advantages of fixed film activated sludge combined with aeration tank (IFAS)

v Aeration tank increases microbial population

Increase processing capacity and load, but do not increase the back-end sedimentation tank load.

v Processing capacity and load capacity is larger

The microbial quantity and biological phase increase per unit pool volume, saving the space required by the pool body.

v Improve precipitation characteristics

The resulting colloidal particles are heavier and more likely to precipitate.

v Sludge production decreased

There are many biological facies and the biological chain is longer. It is similar to the big fish eating small fish. The amount of small microorganisms discharged is reduced and the amount of sludge is reduced.

v Strengthen aeration tank capacity

Improve the impact tolerance of water quality and quantity change of incoming sewage, and carry out nitrification (aerobic) at the same time.

v Constant mode of operation

The operation mode is similar to activated sludge tank, and the sludge bulking condition does not occur, and the concentration of MLSS in the tank has less influence on the treatment efficiency

v Low improvement cost

The existing activated sludge tank can be improved by adding microbial carrier, and the outlet of the tank can be fitted with the screen (to prevent carrier loss). The aeration capacity can be improved according to the demand, which is simple and fast, and the required cost is the least.

Application field

Municipal sewage plant, water plant

COD/BOD/TOC degradation and removal, Nitrification, De-nitrification

Industrial wastewater plant,The paper industry,Chemical, petrochemical,Food, Beverage,...Etc.